+

WELCOME TO DETECHCO

Detechco is a specialist in high-tech processing technologies for the gas turbine industry and machine building. Thanks to our advanced expertise in ECD, EDM, Reverse Engineering, Design, CNC milling, turning and welding, we offer a wide range of high-quality solutions. Our expertise focuses on the processing of difficult materials such as Inconel alloys, cobalt alloys, titanium, pure nickel and stainless steel.

Your challenge is in good hands with us. Please contact us for more information.

ALREADY THIRTY YEARS

EXPERIENCE IN

GAS TURBINE

TECHNOLOGY

TECHNIQUES

ECD

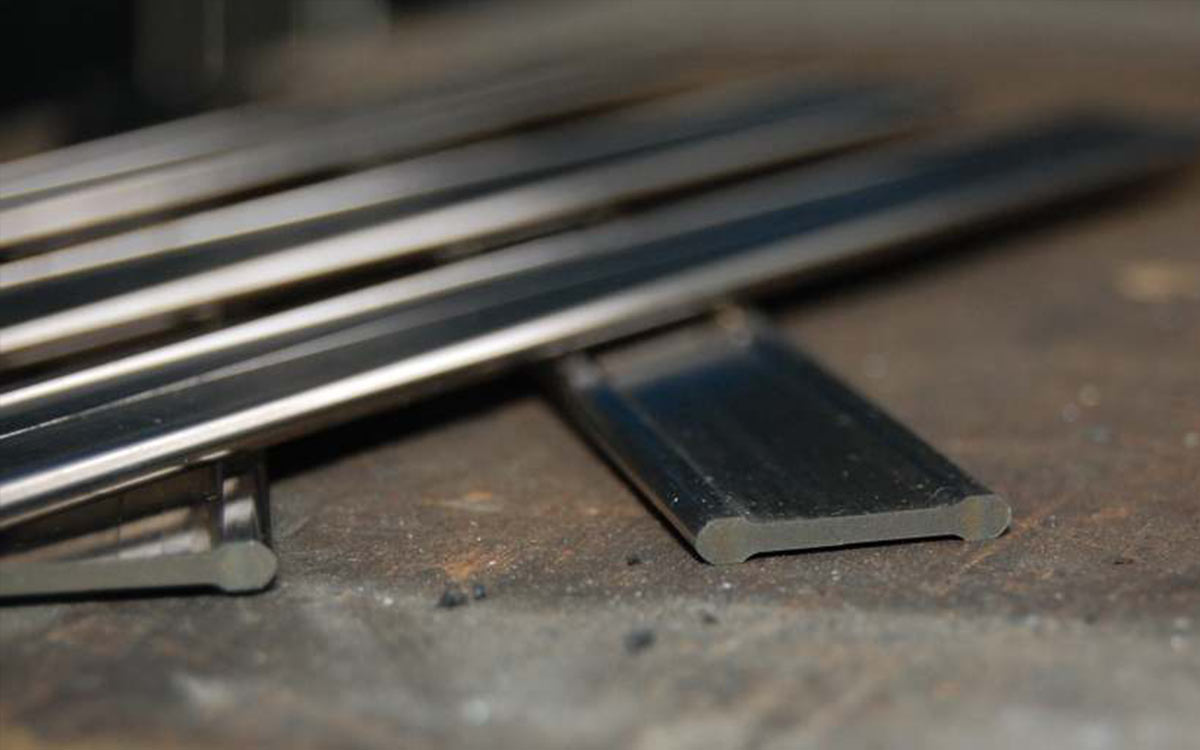

ECD (electro chemical drilling) is a technique that allows non-straight paths to be drilled in hard metals such as gas turbine components. It is an electrolytic process that is also called stem-drilling. The ECD principle works as follows: a product (anode) is hung in acid and a tool (cathode ) is placed. By applying a voltage difference, the particles of the work piece dissolve in the acid. The possibility of drilling holes is created by controlling the operation of this process. Based on many years of experience in ECD, Detechco developed its own advanced machine for this technique: the Techco 5.

EDM

EDM (electro discharge machining) is a process that enables holes and shapes to be reinforced (sparked) into hard material. With EDM or zinc sparks, complex holes and slots can be applied into hard metals, such as Inconel alloys, cobalt alloys, titanium, pure nickel and stainless steel. Detechco uses the Exeron DE35 for EDM and has three machines.

REVERSE ENGINEERING

Reverse engineering is a technique that enables us to remanufacture a product, where we specialise in products for the hot section of industrial gas turbines. We scan the product by means of laser scanning and with the information obtained we create a complete 3D model. Based on that, we cast or mill an exact duplicate.

CNC MILLING

Detechco is a specialist in CNC-controlled milling of difficult material types, such as Inconel 718 and 738, Inconel 625 and Titanium Grade 1 to 5. We also of course have all the expertise in-house for CNC milling of other materials, such as various types of stainless steel, aluminium, steel and all types of plastic. For all our CNC milling operations, we use CAM system One-CNC. We have the following machines: DMU 50V, DMU 50VL, DMU 70V, DMU 50T, DMU 63V.

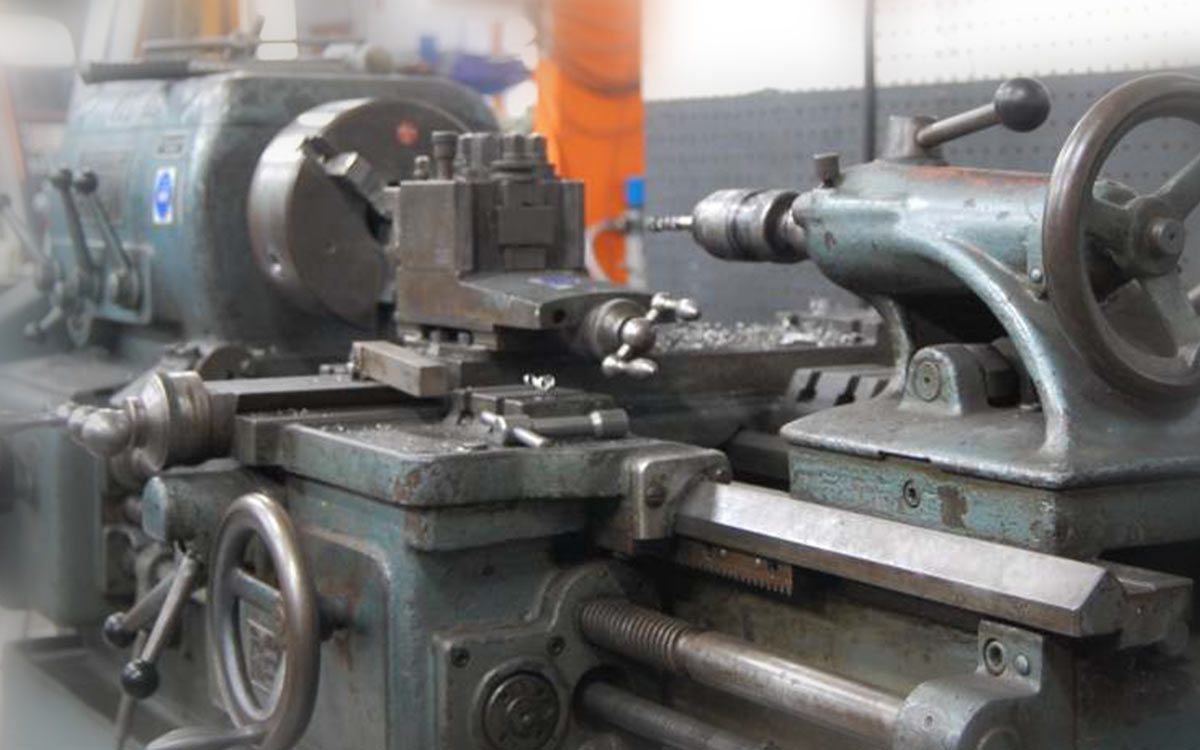

TURNING

Thanks to years of experience, Detechco is a specialist in turning of difficult materials, such as Inconel 718 and 738, Inconel 625 and Titanium Grade 1 to 5. In addition, we have all the expertise in the turning of other materials, such as various types of stainless steel, aluminium, steel and all types of plastic. We use the Gildemeister CTX 400 and the Mazak Nexus 100 Quick Turn.

WELDING

Detechco has the ability and experience to weld all types of turbine components with TIG, TIG in incubator (protective gas) and MIG. Detechco is also here a specialist in welding difficult materials, such as Inconel alloys, cobalt alloys, titanium, pure nickel and stainless steel. Our machines: EWM MIG/MAG, EWM TIG, Welding incubator.

WATCH OUR MOVIE ABOUT...

+

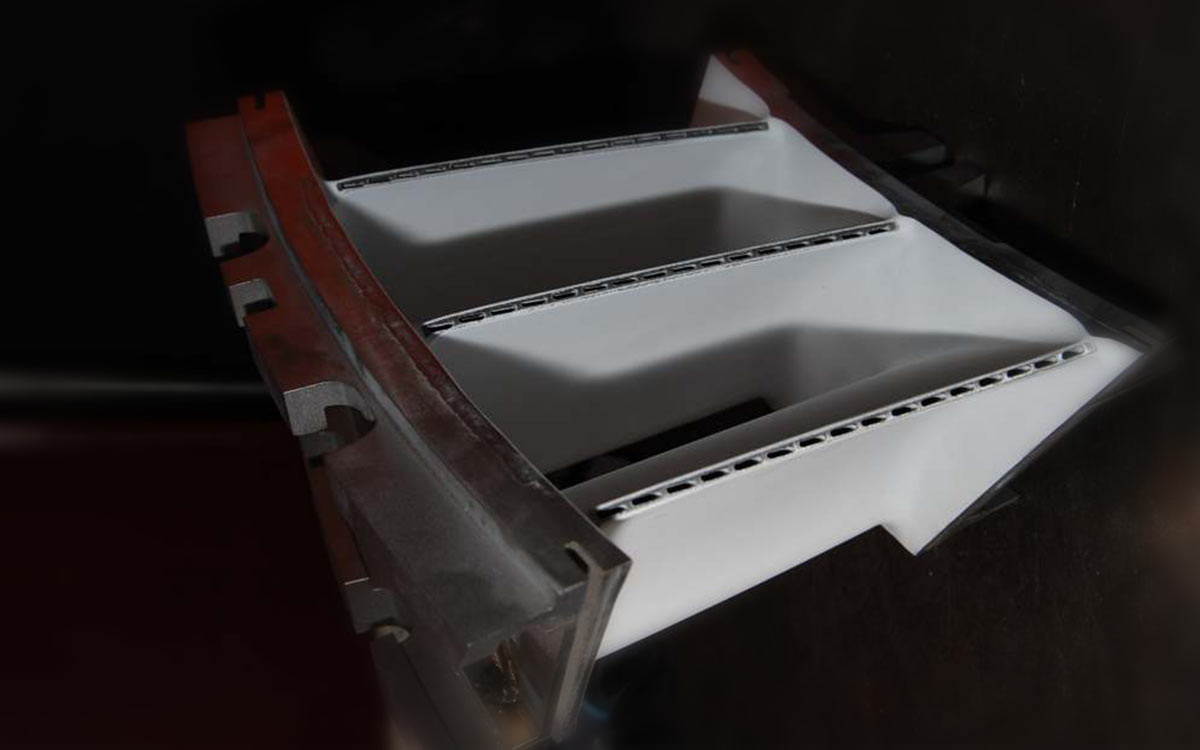

EDM

Here you can see how the Exeron DE 35 cooling slots are reinforced (sparked) 70 mm deep into a gas turbine model. The cooling slots applied here are 1.8 by 9 mm.

PRODUCTS

PROJECTS

OUR LATEST NEWS

ANY QUESTIONS?+31 (0)77-7370080

CONTACT US

US

If you have any questions about us or our production processes, please contact us by using our contact form, or by phone

E-mail: info@detechco.com

Phone: +31 (0)77-7370080

DETECHCO

CONTACT

We are available during office hours

Detechco

Spikweien 36

5943 AD Beringe

The Netherlands

info@detechco.com

+31 (0)77-7370080

- 800 - 1700

- 800 - 1200

SEND A MESSAGE

We will try to reply to your message as soon as possible